Using a back pressure valve alone does nothing to improve fluid flow. Adding a pulsation dampener will improve flow, but standard back pressure valves are not designed to work with dampeners. As pressure varies in the dampener, the back pressure valve negates the dampening effect by opening and closing before the dampener is able to capture a full pulse. Combining the functionality of a pulsation dampener and back pressure valve into a single piece of equipment optimizes the performance of both.

The quick opening and closing of a standard back pressure valves also creates too much flow (gain), resulting in inefficiency and chatter. Blacoh’s Hybrid Valve with patented flow stabilization technology ensures maximum dampening, applies continuous back pressure, and acts as an anti-siphon valve to create a smooth laminar flow with no valve chatter.

PERFORMANCE YOU CAN SEE

Engineered with proven principles for optimum performance, maximum efficiency and simplicity, the Blacoh Hybrid Valve is the all-in-one smart choice in any pumping system. Tests performed using a back pressure valve alone showed no improvement in fluid flow (yellow line in graph below). Fluid flow improves significantly with a pulsation dampener in series (shown in red), but the dampener is not operating at peak efficiency. Nothing matches the outstanding results when the back pressure valve and dampener are replaced with the single construction Hybrid Valve (shown in blue).

- Combines functionality of a pulsation dampener and back pressure valve into one piece of equipment for a smaller footprint and optimal performance.

- Patented tech optimizes dampening, applies continuous back pressure, and acts as an anti-siphon valve to create smooth laminar flow with no valve chatter.

- Proudly made in the USA.

VALVE & DAMPENER IN SERIES VS. HYBRID VALVE

HOUSING MATERIALS: CPVC, PVC, Polypropylene, PVDF, Stainless Steel

BLADDER MATERIALS: Buna-N, EPDM, Hypalon, Neoprene, PTFE, Santoprene, Viton

DIAPHRAGM MATERIAL: PTFE

INLET SIZES: 0.25" (8mm), 0.375" (10mm), 0.5" (15mm)

INLET TYPES: NPT, BSP, Socket Weld 1/2", Flange 1/2", Union 1/2"

VALVE SPRING: 5 to 150 psi (0.3 to 10.3 bar), 5 to 50 psi (0.3 to 3.4 bar)

AIR CONTROL: Chargeable

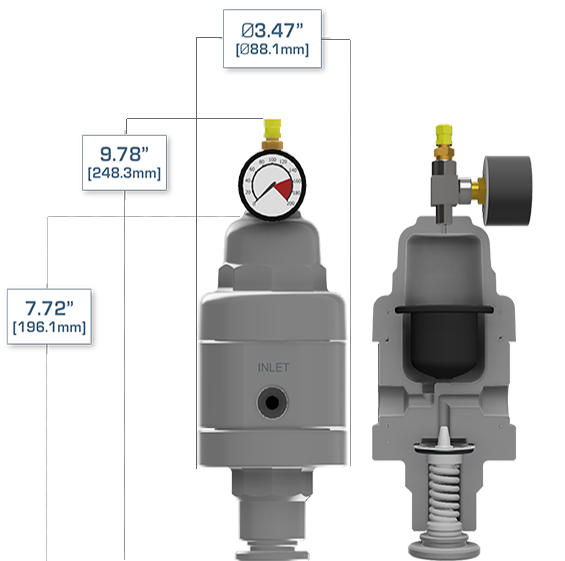

DIMENSIONS

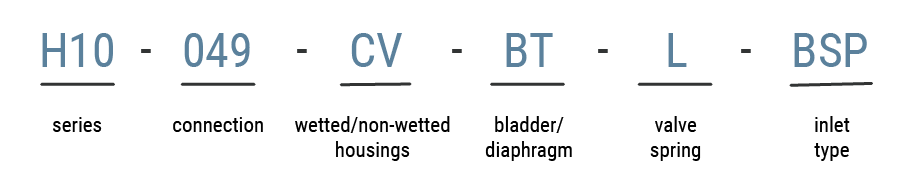

MODEL NUMBER FORMAT

Example model number:

| Field |

Option |

| Connection |

1/4" (025), 3/8" (038), 1/2" (049) |

| Housings |

PVC (V), CPVC (C), Polypropylene (P), PVDF (K), Stainless Steel (S) |

| Bladder |

Buna (B), EPDM (E), Hypalon (H), Neoprene (N), PTFE (T), Santoprene (W), Viton (V) |

| Diaphragm |

PTFE (T) |

| Valve Spring |

5-150 psi (none), 5-50 psi (L) |

| Inlet Type |

NPT, BSP (BSP), Socket Weld 1/2" (SW), Flange 1/2" (F), Union 1/2" (U) |