PULSATION AND YOUR AODD PUMP

Imagine squeezing a tube of toothpaste. Each time you squeeze, a glob of toothpaste has no choice but to move forward. That's exactly how positive displacement pumps work. They create flow by trapping and pushing fluid forward in a steady rhythm - squeeze, release, squeeze, release - much like your heart pumping blood through your body. When you watch the fluid flowing through these pumps (like peristaltic or AODD pumps), you can see this rhythmic pulsing.

When pulsating fluid is being drawn into a pump on the inlet/suction side, it can cause:

- Cavitation

- Vibration and water hammer

- Damage to equipment

- Flow rate issues

- Premature pump failure and inefficiency

The Blacoh SENTRY™ Automatic Inlet Stabilizer (also called a suction stabilizer) is designed for 1.5” and 2” pumps and features a fully automatic air control with integrated venturi valve. It acts as an accumulator to store fluid and release it back into the line as needed. When the pump tries to pull fluid in, instead of creating a harsh pressure drop, the Automatic Inlet Stabilizer releases some of its stored fluid. When the pressure normalizes, the inlet stabilizer refills. It’s like having a small reservoir that smooths out the “gulping” action of the pump. Virtually all acceleration head loss is eliminated because the pump draws fluid from the dampener instead of the pipeline, avoiding the risk of cavitation and ensuring complete chamber fill on each inlet stroke of the pump.

This is particularly important when pumping from a non-pressurized tank or when dealing with viscous fluids that don’t flow easily.

AUTOMATIC AIR CONTROL VALVE

The automatic air control valve specific to the new SENTRY Automatic Inlet Stabilizer (AIS) incorporates a fully integrated, automatic venturi valve designed to accommodate negative pressures within the system. While the venturi valve operates exclusively under vacuum conditions, the AIS itself can create positive pressure to counteract excessive system pressures. During vacuum conditions, the valve lifts the bladder to maintain dampening capabilities.While under positive pressure, it forces the bladder down with compressed air. This dual-control mechanism ensures optimal system performance in both suction & positive pressure conditions.

PRESSURE IS WELL BELOW 10 PSI. WHY IS MY PUMP FAILING?

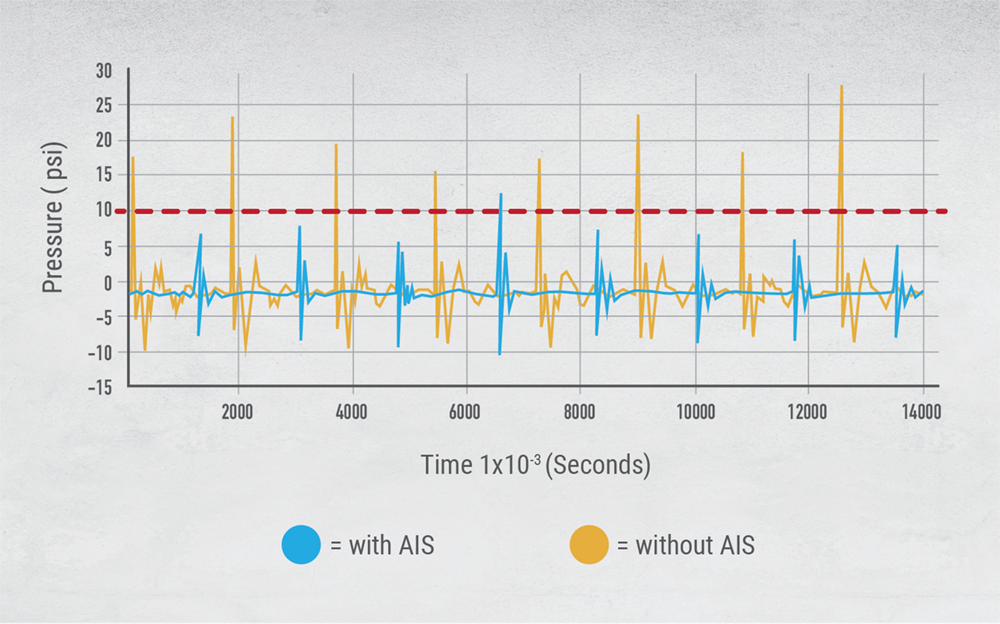

The chart above shows the effect on pump inlet pressure with and without the SENTRY Automatic Inlet Stabilizer (AIS), and compares that to the maximum inlet pressure allowed by the pump manufacturer, which is 10 psi. Even if the average pressure is almost zero, there are acceleration spikes that push well above that limit without the inlet stabilizer.

The AIS decreases pulsation severity, keeping the pressure spikes under that 10 psi limit significantly more often. Furthermore, the AIS helps system pressure stabilize more quickly following a pressure spike.

Decreasing fluid pulsation in this manner will decrease the likelihood of damage being caused to the pump and its components, increasing pump lifespan and ultimately saving money.

You can read more about inlet stabilizers and how they can protect your system on our blog.